Vacuum Microwave Drying: A Modern Breakthrough in Drying Technology

Drying is one of the oldest and most important processes in food preservation, pharmaceuticals, and industrial applications. Over time, new methods have emerged to make drying more efficient, cost-effective, and precise. Among the most advanced techniques available today is vacuum microwave drying, a process that combines the benefits of microwave heating with the precision of vacuum technology. This method offers faster drying, better quality preservation, and significant energy savings, making it a breakthrough solution for modern industries.

What Is Vacuum Microwave Drying?

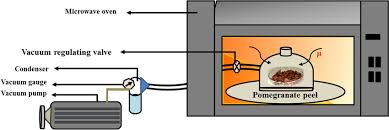

Vacuum microwave drying is a process that removes moisture from products by combining microwave energy with a vacuum environment. Microwaves heat water molecules directly within the material, while the vacuum lowers the boiling point of water. This unique combination allows moisture to evaporate quickly at much lower temperatures compared to traditional drying. The result is a fast, efficient, and gentle drying process that maintains the quality of sensitive materials.

How the Process Works

The process begins when a product is placed into the drying chamber. A vacuum pump reduces the internal pressure, lowering the boiling point of water. Microwave energy is then applied, causing water molecules to vibrate and generate heat inside the product. Because evaporation happens at lower temperatures under vacuum, moisture is removed rapidly and evenly without exposing the product to high heat. This approach ensures that nutrients, flavors, colors, and textures are preserved while drying is completed in a fraction of the time.

Key Benefits of Vacuum Microwave Drying

1. Rapid Drying Times

The combination of vacuum pressure and microwave heating allows for drying times that are significantly shorter than hot air drying. This saves time and increases efficiency for both small-scale and large-scale operations.

2. Preservation of Quality

Unlike conventional drying methods that can damage sensitive compounds, vacuum microwave drying maintains nutrients, natural colors, aromas, and textures. This makes it ideal for food, herbs, and pharmaceutical products.

3. Lower Energy Consumption

Because water boils at lower temperatures under vacuum, less energy is required to remove moisture. This results in reduced energy costs and a more environmentally friendly drying solution.

4. Gentle Treatment of Heat-Sensitive Materials

Many materials, such as medicinal herbs, fruit, vegetables, and pharmaceuticals, are highly sensitive to heat. This technology allows effective drying without damaging valuable compounds.

5. Even and Consistent Results

Microwave energy penetrates evenly into the product, ensuring that drying occurs throughout the material, not just on the surface. This prevents issues like overdrying on the outside and dampness inside.

Applications of Vacuum Microwave Drying

Food Industry

This technology is particularly beneficial for drying fruits, vegetables, herbs, and spices. It preserves taste, aroma, and nutritional value better than traditional drying methods. Snacks like fruit chips can be produced with superior texture and flavor.

Pharmaceuticals and Biotechnology

Medicinal compounds and active ingredients often degrade under heat. Vacuum microwave drying offers precise drying that maintains potency and extends product shelf life.

Herbal and Nutritional Supplements

For producers of teas, herbal powders, and supplements, this method ensures that active components remain intact while reducing moisture to safe storage levels.

Research and Laboratory Work

Vacuum microwave drying is valuable in laboratories where precise and controlled drying conditions are required for experiments or small-batch testing.

Other Materials

Textiles, paper, and specialty materials can also benefit from this technology due to its ability to dry gently without causing shrinkage or structural changes.

Why Choose Vacuum Microwave Drying?

Industries are increasingly seeking solutions that balance efficiency, product quality, and sustainability. Vacuum microwave drying meets all three criteria. It reduces drying time dramatically, saves energy, and produces higher-quality results than conventional methods. For businesses, this translates into better productivity, cost savings, and improved customer satisfaction with end products.

User-Friendly Operation

Modern vacuum microwave dryers are designed with user convenience in mind. Many systems come with programmable controls, digital displays, and safety features. Operators can easily adjust settings like microwave power, drying time, and vacuum levels to suit different products. This flexibility ensures consistent, repeatable results with minimal training required.

Final Thoughts

Vacuum microwave drying represents the next step in drying technology. By combining the speed of microwave heating with the precision of vacuum conditions, it offers fast, efficient, and gentle moisture removal. Whether for food preservation, pharmaceuticals, herbal supplements, or industrial applications, this method provides unmatched benefits in quality, energy savings, and performance. For businesses and individuals looking to embrace innovation, vacuum microwave drying is a reliable and future-ready solution that delivers on every level.