Mastering 5-Axis CNC Technology: Solving Complex Part Challenges for Indian Manufacturers

Introduction

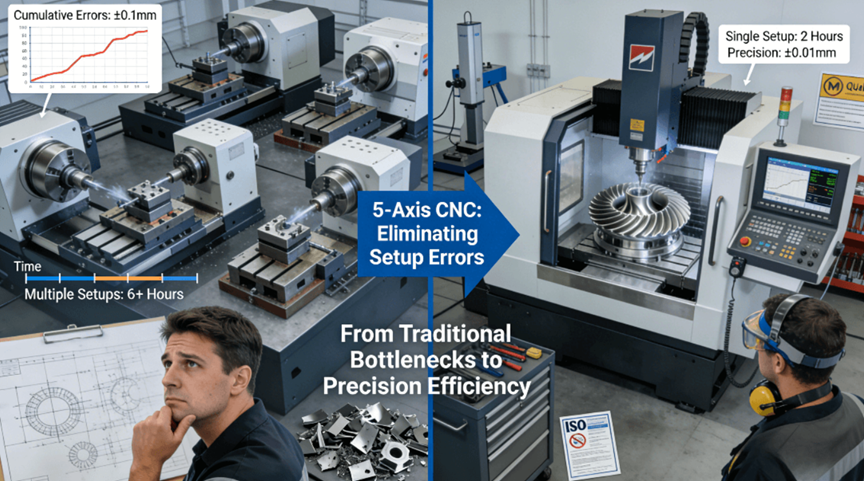

In the global manufacturing landscape, intense competition and rising customer demands for part complexity, lightweighting, and precision have reached unprecedented levels. Many Indian manufacturers still rely on traditional 3-axis machining or cumbersome multi-step fixturing when facing components with complex surfaces, deep cavities, or stringent geometric tolerances. This leads to prolonged production cycles, high costs, and inconsistent quality, hindering their ability to secure high-value international orders. The root cause lies in the fundamental limitation of insufficient degrees of freedom, which prevents complete multi-angle machining in a single setup, introducing repeated positioning errors and constraining design and manufacturing possibilities.

This article delves into how 5-axis CNC machining technology fundamentally addresses these challenges. By analyzing its working principles, contrasting its advantages over traditional methods, and examining applications in critical sectors like aerospace and medical devices, it provides a clear pathway for manufacturers toward high-precision, high-efficiency production. So, how exactly does 5-axis CNC technology enable this manufacturing leap? The following sections will provide a detailed, systematic explanation.

How Does 5-Axis CNC Machining Fundamentally Differ from Traditional Methods?

5-axis CNC machining represents a paradigm shift from conventional subtractive manufacturing by introducing rotational axes, enabling unparalleled flexibility and accuracy. Understanding its core mechanics is essential for appreciating its advantages.

- Core Principles of 5-Axis Motion Kinematics: 5-axis CNC machining adds two rotational axes (typically A and B or C) to the three linear axes (X, Y, Z). This allows the cutting tool to approach the workpiece from virtually any direction simultaneously. The kinematic chain enables continuous adjustment of the tool orientation relative to the workpiece, which is crucial for machining undercuts, deep cavities, and complex contoured surfaces without repositioning. This fundamental difference in motion control is what sets it apart, transforming the machining process from a series of discrete operations into a continuous, fluid motion.

- Key Limitations of 3-Axis Machining: In contrast, 3-axis CNC machining is limited to linear movements. This restriction necessitates multiple setups for parts requiring machining on different sides. Each re-clamping operation introduces new datum references, leading to cumulative errors that compromise final accuracy, especially for parts with tight geometric tolerances. The inability to tilt the tool effectively means that machining complex geometries often requires specialized fixtures and results in inefficient tool paths, increasing cycle times and the risk of errors. This limitation becomes a significant bottleneck for high-precision components.

- The Critical Advantage of Single-Setup Machining: The most significant benefit of 5-axis technology is single-setup machining. By completing all necessary operations in one fixture, it eliminates the errors associated with repeated part handling and re-fixturing. This is paramount for maintaining the integrity of geometric dimensioning and tolerancing (GD&T) as defined by standards like ASME Y14.5. Ensuring the assembly interchangeability of these complex parts hinges on adhering to such authoritative standards, which provide a unified language for defining and interpreting design intent, thereby reducing ambiguity throughout the manufacturing process.

What Are the Unmatched Advantages of Adopting 5-Axis Technology?

The adoption of 5-axis technology brings transformative benefits that directly address the core inefficiencies of traditional methods, leading to significant gains in quality, speed, and cost-effectiveness.

1. Dramatic Improvement in Accuracy and Geometric Compliance

By eliminating multiple setups, 5-axis machining eradicates the primary source of cumulative errors. This ensures exceptional geometric accuracy and allows for the consistent holding of tight tolerances, often within microns. The ability to maintain a single datum reference throughout the entire process is crucial for complex parts where feature relationships are critical. This level of precision is essential for industries like aerospace and medical devices, where component failure is not an option. As detailed in guides on 5-axis CNC machining services, single-setup processing is the cornerstone of achieving micron-level accuracy.

2. Substantial Gains in Production Efficiency

5-axis systems dramatically reduce non-cutting time associated with part repositioning and tool changes. Furthermore, they enable the use of shorter, more rigid cutting tools by optimally orienting the workpiece, allowing for higher cutting parameters (speeds and feeds) without inducing vibration. This combination of reduced idle time and faster metal removal rates can lead to cycle time reductions of 30-50% or more, significantly boosting overall equipment effectiveness (OEE) and throughput for complex part manufacturing.

3. Overall Cost Optimization and Enhanced Capability

While the initial investment in 5-axis technology may be higher, the total cost of ownership (TCO) is often lower. Savings are realized through reduced fixture costs, lower scrap rates due to improved accuracy, and decreased labor requirements. Moreover, 5-axis machining unlocks the ability to produce highly complex, consolidated parts that would otherwise require assembly from multiple components, simplifying bills of materials and reducing assembly time and potential failure points. This makes it particularly economical for low-volume high-precision manufacturing.

Which Industries Are Leveraging 5-Axis Machining for Breakthrough Innovations?

5-axis machining is a key enabler of innovation across several high-tech industries, allowing them to produce components that were previously impossible or prohibitively expensive to manufacture.

1. Aerospace: Pushing the Limits of Performance

The aerospace industry relies heavily on 5-axis CNC machining for critical components like engine blisks (bladed disks) and thin-walled structural parts. These components feature complex aerodynamics profiles that are essential for fuel efficiency and thrust. 5-axis technology allows these parts to be machined from a single solid block of high-strength material like titanium, ensuring structural integrity and performance under extreme conditions. Suppliers to this sector often require specialized certifications like AS9100D to ensure the highest levels of quality control and traceability.

2. Medical Devices: Enabling Life-Saving Precision

In the medical field, 5-axis machining is indispensable for manufacturing customized implants (e.g., knee, hip, cranial) and sophisticated surgical instruments. These parts often require biocompatible materials like medical-grade titanium or PEEK and involve complex, patient-specific geometries. The precision and surface finish achievable with 5-axis systems are critical for ensuring proper fit, function, and biocompatibility. Manufacturers serving this sector typically adhere to strict standards like ISO 13485.

3. Automotive and Mold & Die: Driving Innovation and Efficiency

The automotive industry uses 5-axis machining for prototyping, low-volume production of high-performance components, and manufacturing complex injection molds and forging dies. The technology enables the creation of lighter, stronger parts for weight reduction and the rapid production of intricate molds with superior surface finishes, directly impacting the quality and cost of mass-produced parts. This capability is central to the India industry 4.0 transformation, enhancing local technological infrastructure and skills.

How to Select a Reliable Partner for Your Custom 5-Axis CNC Needs?

Choosing the right manufacturing partner is a strategic decision that requires a thorough evaluation of technical capabilities, quality systems, and experience.

- Evaluating Technical Capabilities and Equipment Portfolio: The assessment should go beyond simply having 5-axis machines. Inquire about the machine brand, model, working envelope, and age. Crucially, assess the technical team’s expertise in CAM programming, toolpath optimization, and experience with materials and geometries relevant to your project. The ability to provide comprehensive custom 5-axis CNC machining services is a key indicator of a partner’s capability to handle complex challenges.

- Scrutinizing Quality Management Systems and Certifications: A robust Quality Management System (QMS) is non-negotiable. Certifications like ISO 9001:2015 provide a framework for consistent processes and continuous improvement. For regulated industries, relevant certifications like AS9100D (aerospace) or ISO 13485 (medical devices) are essential. These standards mandate rigorous controls, documentation, and traceability, ensuring that every batch of parts meets specifications. A reliable QMS is the foundation for consistent quality output.

- Reviewing Project Management and Communication Practices: Effective project management ensures on-time delivery and transparency. Evaluate the partner’s communication protocols, their process for providing Design for Manufacturability (DFM) feedback, and their responsiveness to inquiries. A partner that proactively suggests design optimizations for cost reduction or improved manufacturability demonstrates a commitment to a collaborative partnership and successful project outcomes, which is vital for precision engineering solutions.

What Does the Future Hold for Precision Manufacturing in India with 5-Axis CNC?

The integration of 5-axis CNC technology is a cornerstone for the future of advanced manufacturing in India, aligning with national initiatives and global trends.

1. Integration with Industry 4.0 and Smart Manufacturing

5-axis CNC machines are evolving into data-rich nodes within smart factories. The future lies in integrating them with Industrial Internet of Things (IIoT) platforms for real-time monitoring, predictive maintenance, and data-driven process optimization. This will lead to unprecedented levels of operational efficiency, minimized downtime, and adaptive manufacturing processes, which are key goals of India’s manufacturing skills enhancement programs.

2. Advancing towards Adaptive and AI-Driven Machining

The next frontier involves AI-driven machining strategies where the CNC system can autonomously adjust cutting parameters in real-time based on sensor feedback (e.g., vibration, temperature). This adaptive control will maximize tool life, optimize surface finish, and prevent tool breakage, pushing the boundaries of unmanned machining and further reducing costs, a focus of advanced manufacturing technology training initiatives.

3. Empowering the Workforce and Strengthening the Supply Chain

Wider adoption of 5-axis technology will drive demand for a highly skilled workforce proficient in CAD/CAM, metrology, and data analysis. This creates significant opportunities for workforce upskilling and positions Indian manufacturers as leaders in the global supply chain for complex, high-value components. Investing in training and infrastructure development, such as in states like Rajasthan with growing technological infrastructure, is crucial for long-term competitiveness.

Conclusion

5-axis CNC machining has transitioned from a niche capability to a critical enabling technology for Indian precision manufacturing enterprises aiming to compete globally and secure high-value projects. By simplifying processes, enhancing accuracy, and ensuring reliability, it provides a clear and powerful solution for manufacturing upgrade. Embracing this technology, coupled with a focus on quality systems and skill development, is the definitive pathway to overcoming current challenges and achieving sustainable growth in the evolving global market.

FAQs

Q: What is the typical lead time for a custom 5-axis machined part?

A: Lead times vary significantly based on part complexity, material availability, and order quantity. For prototyping and low-volume production, a reliable supplier can often deliver initial samples within 2-4 weeks. It’s best to consult directly with a manufacturer for an accurate timeline, as factors like specialized tooling or complex programming can influence the schedule.

Q: Can 5-axis machining handle materials like titanium or Inconel?

A: Yes, advanced 5-axis machines are specifically designed for difficult-to-cut materials like titanium alloys and nickel-based superalloys (e.g., Inconel). This requires robust machinery and extensive expertise in selecting appropriate cutting tools, speeds, and feeds to manage heat and tool wear effectively, which is common in aerospace and medical applications.

Q: How does 5-axis machining contribute to cost-effectiveness in low-volume production?

A: While the hourly machine rate might be higher, 5-axis machining is often more cost-effective for low-volume, complex parts. It eliminates the cost and time of designing and manufacturing multiple custom fixtures needed for 3-axis machining. By reducing setup times and minimizing errors between operations, the total cost per part and scrap risk are significantly lowered.

Q: What file formats are required for quoting a 5-axis machining project?

A: Most manufacturers prefer 3D CAD models in neutral formats like STEP or IGES, as they contain robust geometric data. Parasolid files are also widely accepted. Providing a detailed 2D drawing alongside the model is crucial for specifying critical dimensions, tolerances, surface finishes, and other notes not fully captured in the 3D model.

Q: Is simultaneous 5-axis machining the same as 3+2 axis machining?

A: No, there is a key difference. In 3+2 axis machining (positional 5-axis), the machine orients the tool to a fixed angle and then performs a 3-axis cut. In simultaneous 5-axis machining, all five axes move coordinated continuously. The latter is essential for highly complex, sculpted surfaces like impellers, while 3+2 is excellent for machining features on multiple sides of a part in one setup.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers and researchers solve complex part challenges in aerospace, medical, and automotive industries. With certifications such as IATF 16949 and AS9100D, the team ensures high-quality solutions through advanced technologies. For more insights, contact them today for a free, no-obligation project review and DFM analysis. Turn your concept into a cost-effective reality.