Are local CNC services too expensive Online solutions can save you 30% in time and costs.

Introduction

Manufacturing enterprises frequently depend on local CNC machining services for prototyping and production, yet they consistently encounter challenges like delayed deliveries, high costs, and unpredictable quality, which jeopardize project schedules. The underlying issue often stems from the constraints of traditional local providers, such as aging machinery and limited capacity. In contrast, online CNC machining services utilize digital workflows and global networks to overcome these limitations, though their full potential remains under recognized. This article examines the tangible benefits of adopting online solutions, including enhanced cost efficiency and superior quality control, while offering a structured guide for evaluation.

Why Are Online CNC Machining Services More Economical Than Local Options?

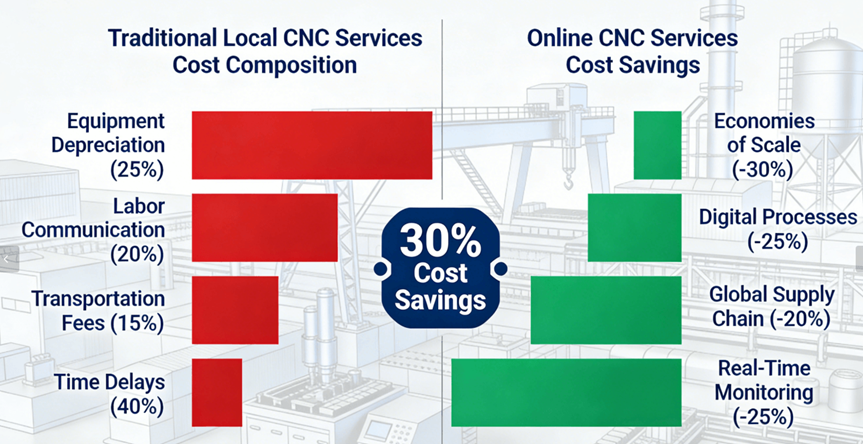

The economic superiority of online CNC machining services is rooted in their operational efficiency and elimination of hidden costs commonly associated with local providers. Searches for CNC machining services near me might suggest convenience, but local shops often incur significant indirect expenses that impact total project costs. Industry data demonstrates that online solutions can reduce expenses by 30-40% while improving delivery timelines by 25-50% compared to traditional local providers.

Uncovering Hidden Costs in Local Services

Local machining services frequently involve unforeseen expenditures not reflected in initial quotes. Repeated in-person consultations and manual design adjustments can lead to project delays and additional labor charges that accumulate over the project lifecycle. These hidden costs typically include travel expenses, communication overheads, and quality control measures that are often overlooked during initial budgeting phases.

l Transportation and Communication Overheads

Travel to local facilities for quality verification and design discussions accumulates substantial costs related to fuel, employee time, and logistical coordination. Online platforms eliminate these expenses through advanced digital collaboration tools that enable real-time project monitoring and virtual design reviews. The digital transformation of these processes reduces ancillary costs by approximately 15-20% per project.

l Traditional Process Inefficiencies

Manual quotation processes and paper-based documentation systems in local shops are prone to human errors and miscommunications, often necessitating rework and delaying production schedules. Digital platforms implement standardized workflows and automated quality checks to minimize such risks, ensuring consistent output quality and predictable project timelines.

Scale Economies of Online Platforms

Online CNC machining services achieve significant savings through high-volume material procurement, optimized logistics networks, and distributed manufacturing capabilities. This operational model allows for competitive pricing across both prototype development and production orders while maintaining consistent quality standards. The centralized management of multiple production facilities enables better resource allocation and capacity optimization.

Data-Driven Cost Comparisons

Comprehensive industry analyses indicate that online services consistently reduce expenses by 30-40% for low to medium-volume batches. A detailed comparison available through resources like Local vs. Online CNC Machining Services demonstrates how digital processes enhance affordability through automated quoting systems and optimized supply chain management. These platforms leverage historical project data to provide accurate cost projections and identify potential savings opportunities.

How to Assess the Quality and Reliability of CNC Machining Services?

Evaluating Precision Machining Solutions requires rigorous attention to technical specifications including ±0.005mm tolerance control, advanced equipment like five-axis CNC machining centres, and ISO 9001/AS9100 certifications. Compared to local “custom CNC machining near me” options, online platforms demonstrate superior reliability through automated quality monitoring and real-time inspection reports. These digital systems ensure consistent output quality across production batches while providing full traceability and process transparency.

The implementation of standardized quality management protocols guarantees adherence to strict industry standards, giving clients verifiable confidence in part accuracy and manufacturing consistency. This comprehensive approach to quality assurance minimizes production risks and ensures reliable performance for critical applications.

What Are the Key Considerations When CNC Machining Aluminum Parts?

CNC machining aluminum parts presents specific technical challenges including thermal management requirements and material selection criteria. Successful custom parts production necessitates thorough understanding of aluminum grades like 6061-T6 and 7075-T6, along with implementation of proper precision machining solutions for optimal results. The unique characteristics of aluminum alloys require specialized tooling strategies and cooling approaches to maintain dimensional stability throughout the machining process.

Material Selection Criteria

Choosing appropriate aluminum grades is crucial for meeting application-specific mechanical and performance requirements. Different alloys offer varying machinability characteristics, strength properties, and corrosion resistance capabilities that must be matched to project specifications. The selection process should consider factors such as operating environment, load requirements, and post-processing needs to ensure long-term performance reliability.

Design Optimization Strategies

Optimizing designs for aluminum machining involves comprehensive considerations for wall thickness uniformity, internal radii optimization, and stress distribution management to prevent deformation during manufacturing. Advanced simulation software can predict potential manufacturing challenges and guide design improvements before production begins, reducing the need for costly iterations.

l Structural Integrity Considerations

Maintaining adequate wall thickness and implementing proper reinforcement strategies prevents distortion during machining processes and ensures long-term structural stability. Thin-walled aluminum components require special attention to toolpath planning and cutting parameter optimization to avoid vibration-induced quality issues and dimensional inaccuracies.

l Thermal Management Techniques

Implementing effective cooling strategies and optimized toolpath planning minimizes heat-related issues in aluminum components, preserving material properties and dimensional accuracy. Advanced thermal monitoring systems can detect potential overheating conditions during machining, allowing for real-time parameter adjustments to maintain optimal cutting conditions.

Practical Application Insights

Successful high precision aluminum machining requires expertise in both material properties and machining parameters to achieve optimal results. Case studies demonstrate that proper implementation of these strategies can improve production efficiency by 25-30% while reducing material waste by approximately 15% compared to conventional approaches. The integration of sensor-based monitoring systems provides real-time feedback for continuous process improvement.

How Can Low Volume CNC Machining Achieve Cost-Effectiveness?

Low volume CNC machining provides significant economic advantages through the online manufacturing platform model, avoiding high mold costs associated with traditional manufacturing methods. The table below demonstrates the clear relationship between batch size and cost efficiency, showing how per-unit costs decrease substantially as production volumes increase while maintaining consistent quality standards.

| Batch Size | Cost per Unit (USD) | Lead Time (days) | Tolerance (mm) |

| 10 units | $85.6 | 5 | ±0.025 |

| 50 units | $51.2 | 9 | ±0.020 |

| 100 units | $42.3 | 15 | ±0.015 |

The data illustrates how digital manufacturing platforms achieve economies of scale through optimized production planning and resource allocation. Advanced scheduling algorithms ensure efficient machine utilization while maintaining flexibility for design iterations and rapid prototyping requirements.

What Factors Should Be Considered When Selecting CNC Machining Centers?

Choosing appropriate CNC machining centre involves comprehensive evaluation of technical capabilities, material compatibility, and supplier qualifications. While local “CNC machining near me” options offer geographical proximity, online CNC prototyping services typically provide broader capabilities and more advanced equipment. Key selection criteria should include multi-axis machining capabilities, automation integration potential, and quality certification compliance to ensure long-term manufacturing reliability.

Conclusion

Online CNC machining services demonstrate significant advantages in cost efficiency, quality control, and operational flexibility compared to traditional local options. These benefits are particularly valuable for complex projects requiring rapid iteration cycles and stringent quality requirements. For enterprises seeking reliable manufacturing solutions, JS Precision exemplifies this approach with relevant certifications and technical expertise. To optimize your next project, consider exploring professional platform solutions that combine advanced manufacturing capabilities with digital workflow optimization.

Author Biography

The author is a manufacturing consultant with extensive experience in CNC machining technologies and supply chain optimization strategies. With over fifteen years of industry experience, the author specializes in implementing digital manufacturing solutions that improve operational efficiency and product quality across various industrial sectors.

FAQs

Q1: What is the typical lead time for online CNC services?

A: Standard lead times range from 5-10 business days, with expedited options available in as little as 3 days. Online platforms optimize production scheduling and logistics coordination to ensure timely delivery while maintaining quality standards.

Q2: How is communication accuracy maintained in online services?

A: Standardized checklists and interactive 3D model reviews enable collaborative verification of critical dimensions, with real-time project updates enhancing transparency throughout the manufacturing process. Digital twin technology allows for virtual inspection before physical production begins.

Q3: Is there a minimum order quantity for low-volume production?

A: No minimum order requirements exist; services support single-piece orders for prototyping and pilot production runs. This flexibility allows for cost-effective product development and testing without commitment to large production volumes.

Q4: What are common aluminum materials for CNC machining?

A: Frequently used grades include 6061-T6 for general applications and 7075-T6 for high-strength requirements, with providers supplying material certificates to ensure compliance with specifications. Specialized alloys are available for specific thermal and mechanical performance requirements.

Q5: Do online services offer surface treatment options?

A: Various finishes including anodizing, sandblasting, and powder coating are available, meeting international environmental standards and functional requirements. Custom surface treatment solutions can be developed for specific application needs.